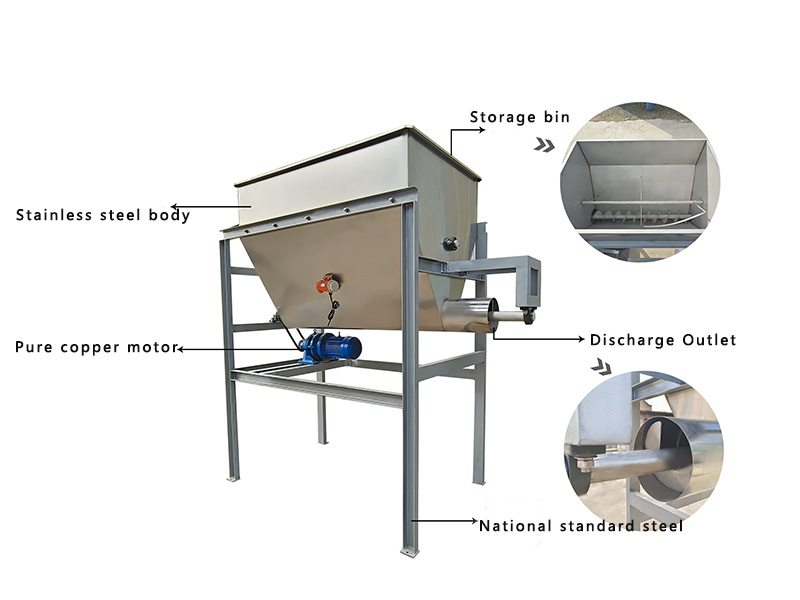

Automatic Feeding Bin

In the automated production line, the automatic feeding bin (also known as the hopper, storage silo) plays the role of material storage, quantitative control and transportation. In the rice noodle production line, the automatic feeding bin is usually used to store raw materials (such as rice, corn, etc.), and the materials are supplied to the downstream processing equipment (such as rice washing machine, pulping machine, etc.) through the conveying system.

Email: yhfoodmachine@163.com

Product introduction

In the automated production line, the automatic feeding bin (also known as the hopper, storage silo) plays the role of material storage, quantitative control and transportation. In the rice noodle production line, the automatic feeding bin is usually used to store raw materials (such as rice, corn, etc.), and the materials are supplied to the downstream processing equipment (such as rice washing machine, pulping machine, etc.) through the conveying system.

Working principle

The automatic feeding bin is mainly composed of a frame, a silo, a vibrator, a bearing, a screw shaft and other components.

During operation, the motor drives the reducer to drive the sprocket and chain, and the screw shaft rotates around the material through the periodic movement of the screw shaft, and the material is made to fall by the action of gravity, so that the material in the machine body continues to fall into the screw shaft, and the material in the middle of the screw shaft is pushed out by the thrust.

Product Parameters

| Model | Production capacity (kg/h) | Motor power (kw) | Dimensions (mm) | Weight (kg) |

| Automatic Feeding Bin | 1000 | 2.2 | 2250*1140*2340 | 220 |

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.