CNC Sports Car Fabric Machine

The CNC Sports Car Fabric Machine for rice noodle production line is a device used to automatically lay raw materials or finished rice noodles during the rice noodle production process. It combines the production process of rice noodles with the automation technology of CNC Sports Car Fabric Machine, and can accurately control the laying, speed and tension of rice noodles, ensuring the uniform laying of rice noodles and avoiding problems such as wrinkles, stretching or breaking during the production process.

Email: yhfoodmachine@163.com

Product introduction

The CNC Sports Car Fabric Machine for rice noodle production line is a device used to automatically lay raw materials or finished rice noodles during the rice noodle production process. It combines the production process of rice noodles with the automation technology of CNC Sports Car Fabric Machine, and can accurately control the laying, speed and tension of rice noodles, ensuring the uniform laying of rice noodles and avoiding problems such as wrinkles, stretching or breaking during the production process.

The CNC Sports Car Fabric Machine has greatly improved production efficiency and quality stability, and is suitable for the high-demand production environment of large-scale production lines.

Features

Improve production quality: Precise CNC to ensure consistent laying quality of rice noodles and reduce quality fluctuations caused by improper manual operation.

Save labor costs: Automated operation greatly reduces manual intervention and reduces labor costs.

Improve production efficiency: The CNC system can accurately control the running speed and cloth amount of the equipment, thereby improving the overall efficiency of the rice noodle production line.

Optimize production process: The CNC sports car fabric machine can adjust the way of laying cloth according to the specific requirements of the rice noodle production process, which improves the flexibility and adaptability of the production line.

Reduce material waste: The equipment can accurately control the conveying amount and laying method of the cloth, avoid excessive material waste, and ensure the cost control of rice noodle products.

Working principle

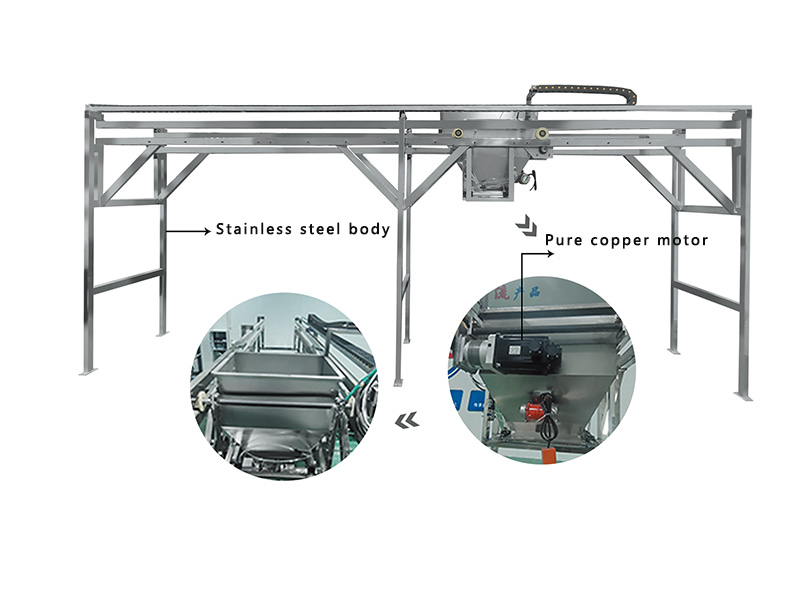

The CNC sports car fabric machine is mainly composed of a rack, a servo motor, a silo, gears, racks and other components. When working, the servo motor drives the gear, and the PLC CNC cabinet and the cylinder automatically make the material in the racing silo accurately put into the main machine feeding hopper.

Product Parameters

| Model | Capacity (kg) | Production capacity (kg/h) | Motor power (kw) | Dimensions (mm) | Weight (kg) |

| CNC Sports Car Fabric Machine | 50 | According to production speed | 3 | 5000*1180*2040 | 180 |

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.