News Detail

Post-Processing of Rice Noodle Products

In order to ensure the quality and taste of the product, rice noodles produced by the rice noodle machine are semi-cooked products and require further processing.

1. Aging Process

- Improving Texture: Freshly made rice noodles may be soft and sticky. The aging process changes the starch structure inside the noodles, making them firmer and more elastic, giving them a smoother texture.

- Better Preservation: Once aged, the rice noodles have a more stable structure, preventing them from sticking together or breaking during storage, thus maintaining their shape.

- Aging Method: Place the rice noodles in a sealed space and let them age for at least 6 hours. During this time, the moisture in the noodles does not evaporate, and the cooling effect is achieved. If the room temperature is low or dry, steam (at 42°C) should be added in the aging room.

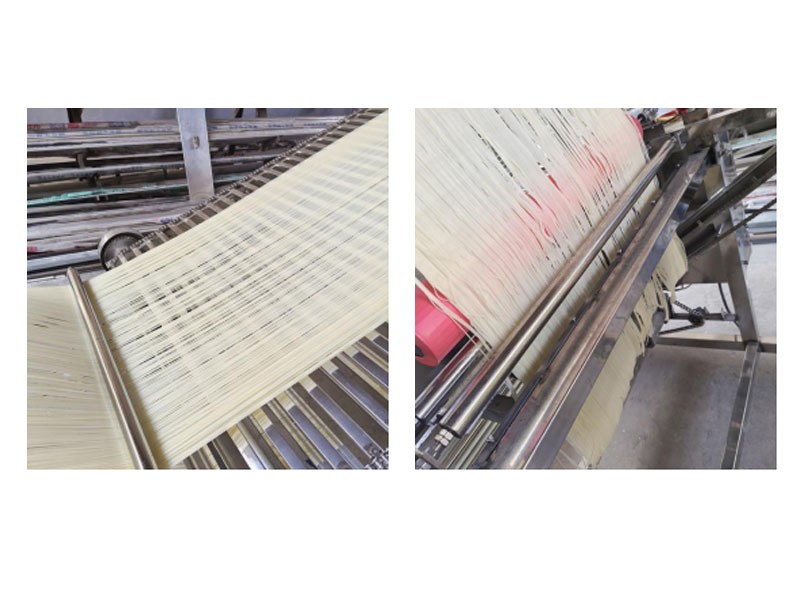

2. Shredding Process

- During production, after cooling and dispersing, the noodles will be separated. However, due to their inherent characteristics, the noodles may still stick together. If not processed, this will negatively affect the texture during cooking.

- Soak the aged rice noodles in cold water.

- After soaking, transfer the noodles to a shredding machine, where they will be separated thoroughly. At this stage, the noodles are considered fresh rice noodles and should be stored in the refrigerator.

3. Drying Process

- The shredded rice noodles need to be dried at low temperatures to become dry rice noodles.

- Drying Method: The drying room should be kept at a temperature of 35°C to 40°C, and the drying process typically takes 8-10 hours. The temperature, wind speed, ventilation, and dehumidification in the drying room are adjusted to ensure proper drying.

- Once dried, the rice noodles are considered dry rice noodles and can be stored and transported at room temperature.

These post-processing steps ensure that the rice noodles maintain a good texture, are easy to store, and are ready for long-term preservation.

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.